In-Depth Guide to CS Pipe Manufacturing Processes in 2024

Explore top-tier CS pipe manufacturing solutions for durable and reliable carbon steel pipes. For more information, use a quick search below.

Carbon Steel (CS) pipes are essential components in various industries, including construction, oil and gas, water supply, and manufacturing. They are known for their strength, durability, and versatility. This guide provides a comprehensive overview of CS pipe manufacturing, including the production process, applications, benefits, and considerations.

What is Carbon Steel Pipe?

Carbon steel pipes are made from carbon steel, a type of steel where carbon is the main alloying element. The carbon content affects the strength, hardness, and ductility of the pipe, making it suitable for a wide range of applications.

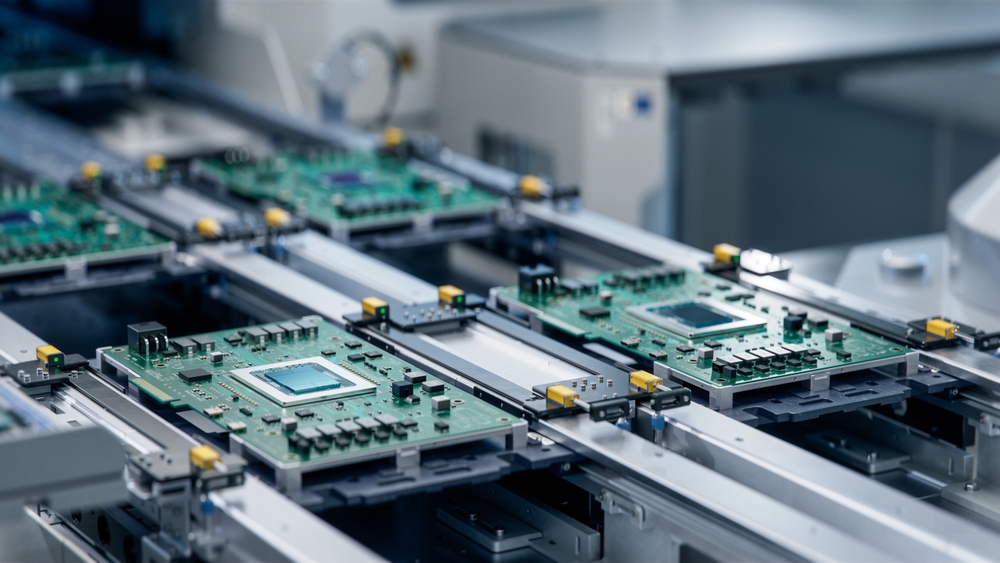

Manufacturing Process of Carbon Steel Pipes

- Raw Material Preparation:

- Steel Production: The process begins with the production of carbon steel billets or blooms from raw iron ore and coke in a blast furnace. The steel is then refined to achieve the desired carbon content and other properties.

- Pipe Formation:

- Hot Rolling: Billets are heated and passed through rollers to form a hollow pipe. This method is typically used for large diameter pipes.

- Extrusion: For smaller diameter pipes, the billet is heated and forced through a die to create the pipe shape.

- Seamless Pipe Production: Involves heating a solid billet and piercing it to create a hollow tube. The tube is then elongated and reduced to the desired dimensions.

- Pipe Finishing:

- Heat Treatment: Pipes may undergo heat treatment to enhance mechanical properties such as strength and toughness. This can include processes like annealing, quenching, or tempering.

- Cold Rolling or Stretching: Further processes are applied to achieve precise dimensions and surface finishes. Cold rolling reduces the pipe's diameter and wall thickness.

- Cutting and Threading: Pipes are cut to specific lengths and may be threaded for connection purposes.

- Inspection and Testing:

- Quality Control: Pipes undergo various tests, including visual inspections, dimensional checks, and non-destructive testing (e.g., ultrasonic or radiographic tests) to ensure they meet industry standards and specifications.

- Pressure Testing: Pipes are tested under pressure to verify their strength and integrity.

- Coating and Packaging:

- Coating: To protect against corrosion, pipes may receive protective coatings such as paint or anti-corrosive wraps.

- Packaging: Finished pipes are packaged and prepared for shipment, ensuring they are protected during transport.

Applications of Carbon Steel Pipes

- Construction:

- Structural Use: Used in building frameworks, support columns, and other structural components due to their strength and load-bearing capabilities.

- Piping Systems: Commonly used for water supply, drainage, and heating systems.

- Oil and Gas:

- Pipeline Construction: Essential for transporting oil, natural gas, and other fluids over long distances. Carbon steel's strength and durability make it suitable for high-pressure applications.

- Manufacturing:

- Industrial Equipment: Used in machinery, equipment, and components requiring high strength and resistance to wear and tear.

- Water Supply and Sewage:

- Piping Systems: Utilized in water distribution systems, sewage pipelines, and other fluid transport applications.

Benefits of Carbon Steel Pipes

- Strength and Durability:

- High Strength: Carbon steel pipes are known for their high tensile strength, making them suitable for demanding applications.

- Longevity: They have a long service life and can withstand harsh environmental conditions.

- Cost-Effectiveness:

- Affordable: Carbon steel is relatively inexpensive compared to other materials, making it a cost-effective choice for many applications.

- Versatility:

- Wide Range of Uses: Suitable for various industries and applications due to their customizable properties and dimensions.

- Fabrication Ease:

- Ease of Processing: Carbon steel pipes are easy to cut, weld, and fabricate, allowing for flexibility in design and installation.

Considerations for Using Carbon Steel Pipes

- Corrosion Resistance:

- Protection Needed: Carbon steel is prone to corrosion, especially in harsh environments. Proper coatings and regular maintenance are necessary to prevent deterioration.

- Mechanical Properties:

- Material Selection: Choose the appropriate grade of carbon steel based on the required mechanical properties, such as strength and hardness.

- Compliance with Standards:

- Industry Standards: Ensure that the pipes meet relevant industry standards and specifications for quality and performance.

- Environmental Impact:

- Sustainability: Consider the environmental impact of carbon steel production and explore options for recycling and sustainable practices.

Carbon steel pipe manufacturing involves a detailed process that includes raw material preparation, pipe formation, finishing, and rigorous testing. Carbon steel pipes are valued for their strength, durability, and cost-effectiveness, making them suitable for a wide range of applications across various industries. By understanding the manufacturing process, applications, benefits, and considerations, you can make informed decisions regarding the use and implementation of carbon steel pipes in your projects.