Carbon Pipe Steel Manufacturing: A Growing Industry

Discover the carbon pipe steel manufacturing industry in Mexico, its processes, key industries, environmental impact, and top manufacturers.

Carbon pipe steel manufacturing is an essential sector in Mexico's industrial landscape, serving a wide array of industries such as construction, oil and gas, and automotive. With the increasing demand for durable and high-quality materials, carbon steel pipes have become a key component in modern infrastructure and manufacturing processes. The country's steel industry is growing rapidly, positioning Mexico as a significant player in the global carbon steel market.

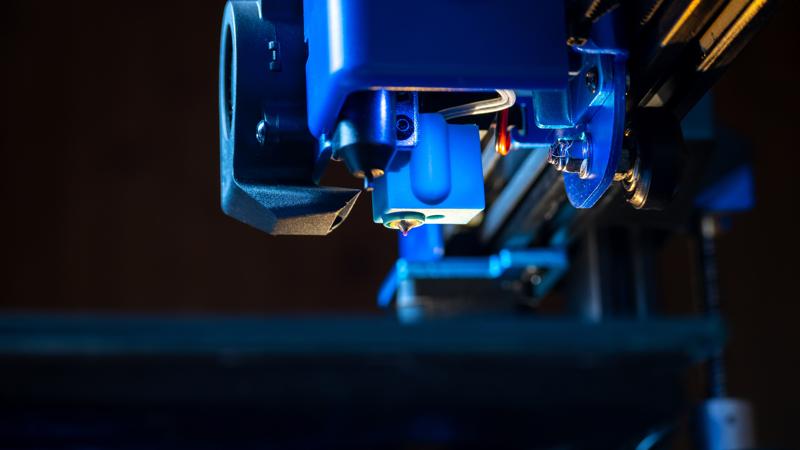

The Process of Carbon Pipe Steel Manufacturing

Carbon pipe steel manufacturing involves several steps, starting with the extraction of raw materials, including iron ore and coal. The process begins by melting these materials in a blast furnace to produce molten steel. This molten steel is then poured into molds to form the desired pipe shapes. Depending on the requirements, the pipes may undergo additional treatments such as annealing, galvanizing, or coating to enhance their strength, durability, and corrosion resistance.

The steel manufacturing process in Mexico adheres to stringent international standards to ensure the quality of the finished product. State-of-the-art technologies are employed to produce pipes that meet industry-specific requirements, offering reliability and performance for various applications.

Advantages of Carbon Steel Pipes

Carbon steel pipes offer a range of benefits that make them an ideal choice for many industries. They are known for their strength and durability, which are crucial in demanding environments like oil pipelines and construction frameworks. Carbon steel’s ability to withstand high pressure and temperature also makes it suitable for transporting gases and fluids in industries such as energy and petrochemicals.

Another advantage of carbon steel pipes is their resistance to wear and tear. They have a long lifespan, which reduces the need for frequent replacements and lowers maintenance costs. Additionally, carbon steel pipes are environmentally friendly, as they can be recycled and reused, making them a sustainable option for industrial applications.

Key Industries Utilizing Carbon Steel Pipes in Mexico

Several industries in Mexico rely on carbon steel pipes for their operations:

- Oil and Gas: The oil and gas sector is one of the largest consumers of carbon steel pipes. These pipes are used for drilling, transporting crude oil, and natural gas pipelines due to their durability and ability to handle extreme conditions.

- Construction: In the construction industry, carbon steel pipes are commonly used for structural frameworks, water supply systems, and building infrastructure. Their strength and versatility make them ideal for various construction applications.

- Automotive: Mexico’s growing automotive sector also depends on carbon steel pipes for exhaust systems, chassis construction, and other mechanical parts that require durability and heat resistance.

- Water and Sewage Systems: Municipal water systems often utilize carbon steel pipes for water distribution and sewage systems due to their resistance to corrosion and ability to handle large volumes of water.

Environmental and Economic Impact of Carbon Pipe Manufacturing in Mexico

The carbon pipe steel manufacturing industry in Mexico plays a crucial role in the country's economic development. As one of the top steel producers in Latin America, Mexico's steel industry generates significant revenue and provides jobs to thousands of workers. Moreover, many steel manufacturers in Mexico are adopting greener practices by using recycled materials and implementing energy-efficient technologies, reducing the industry's environmental footprint.

Mexico’s geographical location, close to both the North American and South American markets, also gives its steel manufacturing sector a strategic advantage in terms of export potential. This makes Mexico an attractive destination for foreign investments in the carbon pipe steel industry.

Cost and Top Carbon Pipe Steel Manufacturers in Mexico

The cost of carbon steel pipes can vary based on the pipe’s dimensions, thickness, and the manufacturing process involved. On average, carbon steel pipes in Mexico can range from $1,500 to $2,500 per ton, depending on the specifications and additional treatments applied.

Some of the top carbon pipe steel manufacturers in Mexico include:

- Ternium Mexico: One of the leading steel manufacturers in Latin America, Ternium produces high-quality carbon steel pipes for a variety of industries. They are known for their modern facilities and compliance with international standards.

- ArcelorMittal Mexico: A major global steel producer, ArcelorMittal has a strong presence in Mexico, offering carbon steel pipes and other steel products for construction, automotive, and energy sectors.

- DeAcero: Based in Monterrey, DeAcero is a prominent steel manufacturer that supplies carbon steel pipes for both domestic and international markets, focusing on sustainability and innovation in production methods.

In conclusion, carbon pipe steel manufacturing in Mexico is a vital industry that supports a range of sectors including oil and gas, construction, and automotive. With its strong infrastructure, advanced technology, and growing emphasis on sustainable practices, the industry continues to thrive. The use of carbon steel pipes offers durability, strength, and long-term cost savings, making them an essential component in various industrial applications. As demand increases and environmental practices improve, Mexico's carbon steel pipe manufacturing sector is set to maintain its significant role in both the domestic and global markets.