Pick and Place Robots: Revolutionizing Automation in Manufacturing and Warehousing

Discover how pick and place robots are transforming automation in manufacturing and warehousing. For more information, use a quick search below.

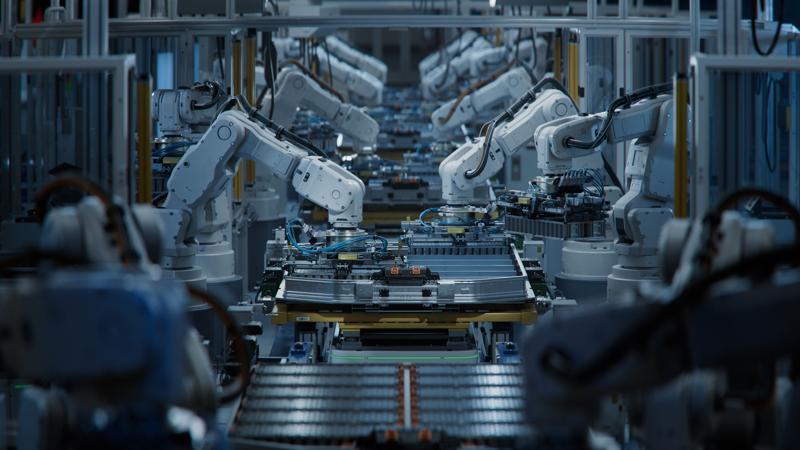

Pick and place robots are transforming the landscape of manufacturing and warehousing by automating repetitive tasks, enhancing precision, and increasing overall efficiency. These versatile robots are designed to handle various tasks such as sorting, assembling, and packaging, making them essential tools in modern industrial operations. This guide explores the advantages, applications, and considerations for implementing pick and place robots in your business.

What Are Pick and Place Robots?

Pick and place robots are industrial robots specifically designed to pick up objects from one location and place them in another. These robots are equipped with robotic arms or grippers that can handle a range of objects, from small components to larger packages. They are commonly used in automated systems to perform tasks that would otherwise require manual labor.

Benefits of Pick and Place Robots

- Increased Efficiency

Pick and place robots can operate continuously without breaks, leading to significant increases in productivity. They can complete tasks faster than human workers, reducing the time required for sorting, assembling, and packaging. - Enhanced Precision and Accuracy

These robots are programmed to handle objects with high precision, minimizing errors and ensuring consistent placement. This accuracy is crucial for applications requiring tight tolerances and reliable results. - Reduced Labor Costs

By automating repetitive and labor-intensive tasks, pick and place robots help reduce labor costs and alleviate the need for manual intervention. This can lead to significant cost savings for businesses. - Improved Safety

Automating hazardous or strenuous tasks with pick and place robots helps improve workplace safety by reducing the risk of injuries associated with manual handling and repetitive motions. - Flexibility and Adaptability

Modern pick and place robots are highly versatile and can be reprogrammed to handle different types of objects or perform various tasks. This flexibility allows businesses to adapt to changing production needs and product variations.

Choosing the Right Pick and Place Robot

- Assess Your Needs

Determine the specific tasks you need the robot to perform, including the size and weight of the objects it will handle, the speed and accuracy required, and the environment in which it will operate. - Evaluate Robot Specifications

Consider the robot’s payload capacity, reach, speed, and precision. Ensure that the robot meets your operational requirements and can handle the types of objects involved in your processes. - Consider Integration and Compatibility

Ensure that the pick and place robot is compatible with your existing systems and equipment. Evaluate the ease of integration and whether the robot can be programmed or reconfigured to fit your needs. - Review Software and Controls

Assess the robot’s software capabilities and control systems. Look for user-friendly programming interfaces and the ability to adapt to changes in production requirements. - Check for Support and Maintenance

Choose a robot manufacturer or supplier that offers reliable support and maintenance services. Ensure that you have access to technical assistance and spare parts if needed.

Implementation and Best Practices

- Plan Your Layout

Design the layout of your production or warehouse space to optimize the placement and movement of the pick and place robot. Ensure that the robot’s reach and accessibility align with your workflow. - Train Your Staff

Provide training for your staff on how to operate and maintain the pick and place robot. Ensure they understand how to program the robot and troubleshoot any issues that may arise. - Monitor Performance

Continuously monitor the robot’s performance to ensure it is operating efficiently and meeting your production goals. Use data and analytics to identify areas for improvement and optimize performance. - Maintain Regularly

Perform regular maintenance and inspections to keep the robot in good working condition. Follow the manufacturer’s recommendations for servicing and address any issues promptly. - Evaluate and Adapt

Regularly evaluate the effectiveness of the pick and place robot in meeting your production needs. Be prepared to make adjustments or upgrades to enhance its performance and adapt to changing requirements.

Pick and place robots are a powerful tool in modern manufacturing and warehousing, offering numerous benefits including increased efficiency, precision, and safety. By understanding their applications, evaluating your needs, and following best practices for implementation, you can effectively leverage pick and place robots to streamline your operations and improve overall productivity. Whether you're looking to automate repetitive tasks or enhance your production capabilities, these robots offer a valuable solution for a wide range of industries.