Top Vacuum Drum Filter Machines Available in 2024

Discover WesTech’s continuous Rotary Vacuum Drum Filters, designed for versatile liquid-solids separation in various industries. For more information, use a quick search below.

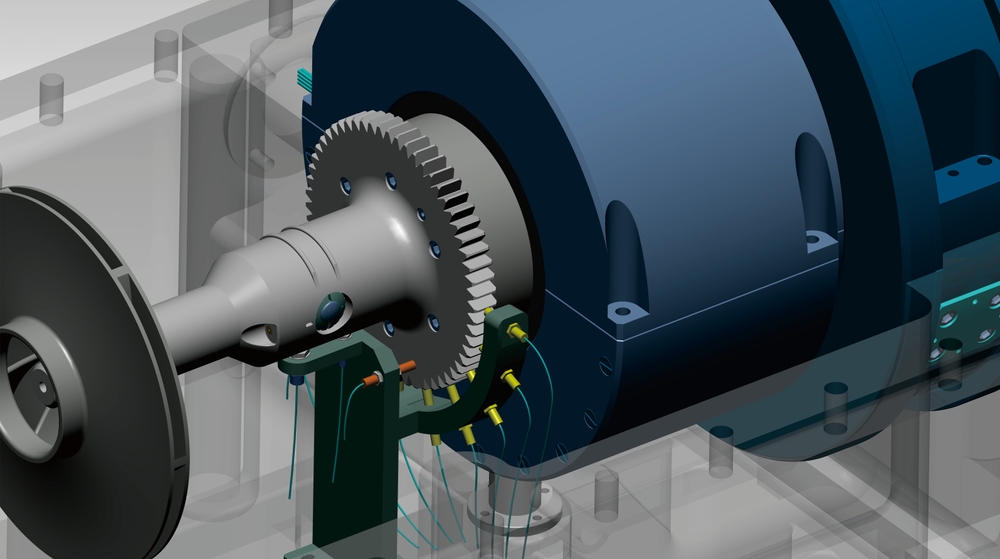

WesTech’s continuous Rotary Vacuum Drum Filters deliver versatile liquid-solids separation solutions tailored to various industrial processing flow sheets. Designed to handle dewatering, washing, and clarification tasks—or a combination thereof—these filters offer unparalleled operating flexibility. Available in sizes up to 13.5 ft in diameter and 36 ft in length, WesTech drum filters are fully customizable to meet specific customer requirements.

Features:

- Scraper Discharge: The most commonly used discharge method. After dewatering, the filter cake is removed by a scraper blade just before the drum is re-submerged. The scraper mainly deflects the cake, dislodged by an air blowback, into the discharge chute.

- Precoat Discharge: Ideal for processes with low solid concentrations or where filter cakes could blind the filter media. This discharge method ensures effective filtration for sensitive materials.

- Roll Discharge: Best suited for thin, sticky cakes that adhere to themselves. The filter cake is pressed against a discharge roll packed with filter cake, which pulls or peels the thin cake from the drum. A knife blade then removes the solids from the discharge roll.

- String Discharge: Designed for thin, unstable cakes that may change from solid to liquid if disturbed. Commonly used in the starch and pharmaceutical industries, this method employs endless strings or wires that pass around the filter drum, guiding the cake to separate as the strings pass over rollers.

- Belt Discharge: Allows for the discharge of filter cakes and the washing of both sides of the filter cloth with each drum rotation. This method is particularly useful for thin, sticky, and wet filter cakes that require additional assistance for proper discharge.

Benefits:

- Enhanced Flexibility: Capable of handling a variety of industrial processes, including dewatering, washing, and clarification.

- Customizable Design: Available in multiple sizes and configurations, tailored to specific application needs.

- Efficient Operation: Various discharge methods ensure optimal performance for different types of filter cakes and processing conditions.

Applications:

- Chemical Processing: Ideal for separating liquid-solid mixtures in chemical production.

- Food & Beverage: Used in processes requiring precise filtration, such as in the production of starch or other food additives.

- Pharmaceuticals: Perfect for handling sensitive materials that require gentle processing.

- Mining & Minerals: Efficiently processes slurry in mineral extraction and refinement.

- Pulp & Paper: Supports dewatering and clarification in pulp and paper manufacturing.

WesTech’s continuous Rotary Vacuum Drum Filters provide a robust and versatile solution for a wide range of industrial liquid-solids separation needs. With their ability to handle dewatering, washing, and clarification tasks, these filters offer unparalleled flexibility and customization options, making them an ideal choice for industries such as chemical processing, food and beverage, pharmaceuticals, mining, and pulp and paper. Whether dealing with thin, sticky, or unstable filter cakes, WesTech's variety of discharge methods ensures efficient and effective operation, tailored to meet the specific demands of your processing flow sheets. Invest in WesTech's Rotary Vacuum Drum Filters for reliable performance and optimized industrial processes.