Grinding Machines in Luxembourg: A Comprehensive Guide to Industrial Precision

Explore the use of grinding machines in Luxembourg's industries. For more information, use a quick search below.

Grinding machines play a crucial role in Luxembourg's industrial landscape, where precision and quality are paramount. These machines are used across various industries to achieve exacting standards in metalworking, manufacturing, and toolmaking. This article explores the types of grinding machines available in Luxembourg, their applications, and the leading suppliers that ensure high-quality, precision grinding in the country.

Understanding Grinding Machines

What is a Grinding Machine?

A grinding machine is a power tool or machine tool used for grinding, which is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation. Grinding machines are essential for achieving fine finishes and high precision in manufacturing processes.

Types of Grinding Machines

- Surface Grinders: Used to produce a smooth finish on flat surfaces. Surface grinders are commonly used in toolrooms and manufacturing plants where high precision is required.

- Cylindrical Grinders: Designed to work on cylindrical shapes. They are ideal for manufacturing precision components such as shafts, rods, and bearing races.

- Centerless Grinders: These machines are used to grind the external diameter of cylindrical workpieces without the need for centers. This method is efficient for mass production and offers high throughput.

- Internal Grinders: Specialized for grinding the internal surfaces of cylindrical or conical workpieces. They are widely used in the production of bearing housings and other precision components.

- Tool and Cutter Grinders: These are versatile machines used to sharpen and recondition cutting tools like drills, end mills, and reamers.

- CNC Grinding Machines: These computer-controlled machines offer precise and automated grinding solutions, allowing for the production of complex shapes with tight tolerances.

Applications of Grinding Machines in Luxembourg

1. Precision Engineering

Luxembourg is home to several precision engineering companies that rely on grinding machines to manufacture components with tight tolerances. These machines are essential for producing parts used in aerospace, automotive, and medical industries, where accuracy is critical.

2. Tool and Die Making

Grinding machines are indispensable in tool and die making, where high-quality tools are manufactured for stamping, cutting, and molding processes. Surface grinders and tool and cutter grinders are particularly important in ensuring that tools are sharp and precisely shaped.

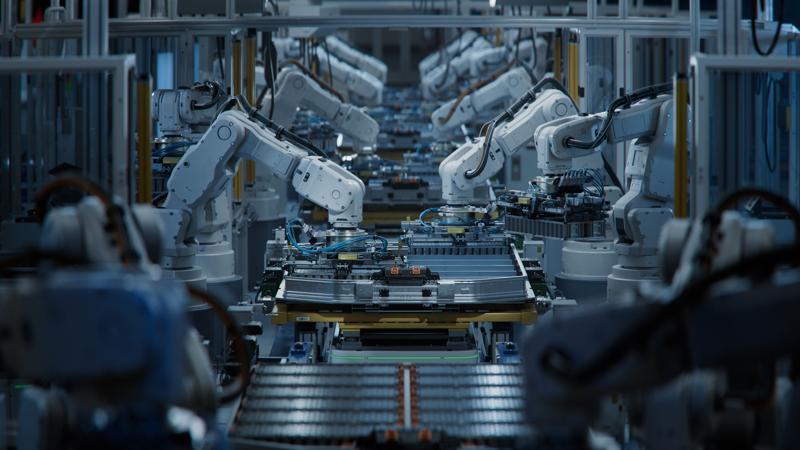

3. Automotive Manufacturing

The automotive sector in Luxembourg benefits from grinding machines in the production of engine components, gears, and transmission parts. Cylindrical and internal grinders are commonly used to ensure the high precision required in these components.

4. Metal Fabrication

In metal fabrication, grinding machines are used to achieve smooth surfaces and remove excess material from metal workpieces. Surface grinders and centerless grinders are frequently employed to produce finished parts that meet stringent quality standards.

5. Maintenance and Repair

Grinding machines are also used in maintenance and repair operations across various industries in Luxembourg. They are essential for refurbishing worn-out parts, restoring them to their original specifications.

Grinding machines are vital to Luxembourg's industrial sector, providing the precision and efficiency needed to produce high-quality components and tools. From surface and cylindrical grinders to advanced CNC machines, the range of grinding solutions available in Luxembourg caters to a wide variety of applications. Whether you are involved in precision engineering, automotive manufacturing, or toolmaking, investing in the right grinding machine is crucial for maintaining competitive standards and achieving operational excellence.